DEMAGNETIZING SERVICES

Degaussing cables surround turbine

Residual magnetism is a concern for most industries. If left undetected, the resultant damage will only compound, triggering unscheduled and costly shutdowns.

Our trained personnel can conduct Magnetic Surveys and On-site Demagnetizing.

Causes of Residual Magnetism

- Magnetic tools such as magnetic chucks, magnetic base drills, and magnetic base indicators

- Magnetic Particle Inspection (MPI)

- Induced magnetism through machining, abrasion,

friction between the parts and tools - Magnetized parts introduced into the machine such as a magnetized gears or bearings

- Prolonged exposure to magnetic fields such as power

lines, the Earth’s magnetic field, etc.

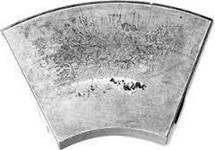

Gas turbine

Consequences in Rotating Equipment Industry

Electrical discharge damage can result in:

- Early wear on components

- Frosting, pitting or spark tracks rotating parts

- Increased operating temperatures

- Melting or welding or couplings and bearings

- False sensor readings and alarms

-

- Electrical runout

- Temperature spikes

- False vibration readings

Consequences in Manufacturing

- Early wear on components

- Attaching/adhering of chips, tools

- Sensor misinformation

- Residual magnetism in end product

- Measurement errors

- Impedes production processes

- Surface irregularities

- Irregularities in chroming processes

- Friction

Damage to thrust bearing